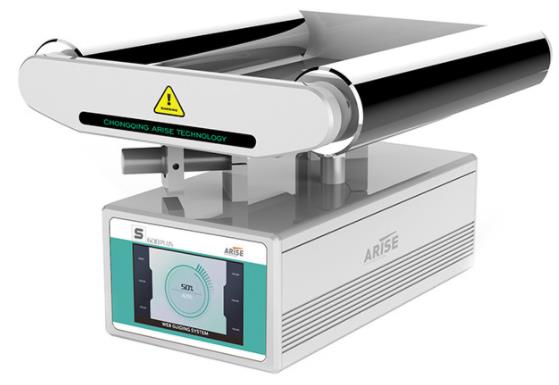

In the dynamic landscape of industrial manufacturing, the pursuit of precision and adaptability has spurred the development of innovative technologies. Among these advancements, web guide systems emerge as vital components, ensuring accurate material alignment and management throughout diverse manufacturing processes. This article delves into the significance of customization and adaptability in web guide systems, examining how these features are revolutionizing industries and optimizing manufacturing operations.

Tailored Solutions for Varied Applications:

Customization lies at the core of effective web guide systems. Industries handling diverse materials, such as paper, film, textiles, and metal, require tailored solutions to address specific challenges. Customizable web guide systems empower manufacturers to adapt technology to the unique requirements of different applications, ensuring optimal performance across various materials and production scenarios.

Flexibility to Accommodate Changing Production Parameters:

Industries operate in a state of constant flux, with evolving production requirements and dynamic variables. Web guide systems equipped with adaptive features can effortlessly accommodate fluctuations in material thickness, width, or tension. This flexibility is invaluable in environments where production conditions frequently change, enabling swift adjustments without compromising precision.

Integration of Advanced Sensors and Controls:

Customized web guide systems often incorporate advanced sensors and controls, enhancing their versatility. Web guide sensors detect changes in web alignment or stress, triggering real-time adjustments to maintain material alignment. Intelligent control systems allow for parameter modifications and fine-tuning based on unique production conditions, optimizing performance.

Remote Monitoring and Control:

The digital era has ushered in remote connectivity and monitoring capabilities for web guide systems. Customizable solutions empower operators to remotely monitor and control web guide systems, facilitating real-time adjustments without physical presence. This enhances convenience and responsiveness, fostering a more efficient production environment.

Precision in Printing and Converting Processes:

Precision is paramount in printing and converting industries. Customized web guide systems ensure accurate registration, minimizing waste and enhancing the quality of printed materials. Whether in flexographic printing, gravure printing, or laminating processes, adaptable web guide systems play a pivotal role in maintaining alignment and registration.

Safety and Reliability Enhancements:

Customization extends beyond performance to include safety features. Industries with stringent safety requirements can tailor web guide systems to incorporate additional safety mechanisms, such as emergency stop functions and redundant sensors. This ensures not only precision but also a high level of reliability and compliance with safety standards.

Energy-Efficient and Sustainable Solutions:

Customized web guide systems increasingly integrate energy-efficient technologies, promoting sustainability. Variable frequency drives, low-energy components, and sophisticated power management systems are combined to deliver personalized solutions that align with the growing emphasis on environmentally friendly practices in modern enterprises.

Conclusion:

The customization and adaptability of web guide systems are pivotal in meeting the evolving needs of industries seeking precision, efficiency, and flexibility. From printing and converting to packaging and textiles, tailored web guide systems have a transformative impact across diverse sectors. As industries embrace customization, the future holds even more innovative solutions that will revolutionize how materials are handled and processed, ushering in a new era of industrial efficiency and reliability.