When it comes to manufacturing, efficiency is key. Streamlining production processes with professional turning services can significantly enhance the overall productivity and quality of output. In this article, we will delve into the various aspects of turning services and how they contribute to optimizing manufacturing operations.

The Role of Turning Services in Manufacturing

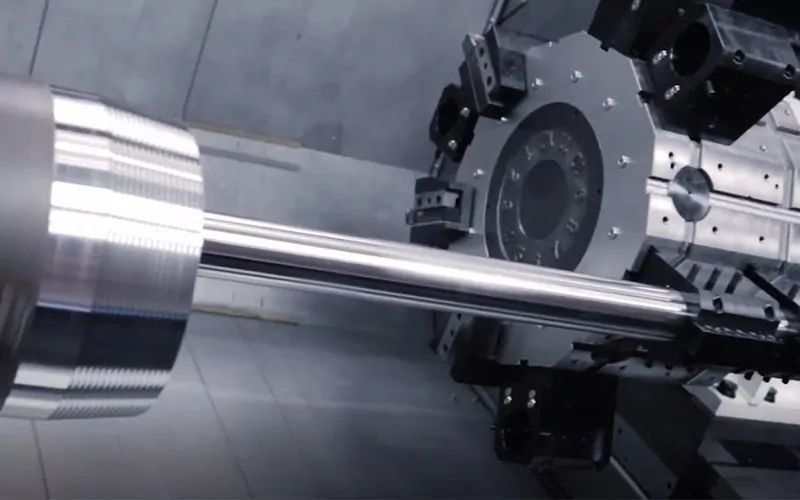

Turning services play a crucial role in the manufacturing industry, particularly in the production of components with rotational symmetry. By utilizing advanced turning techniques, manufacturers can create precise and intricate parts that are essential for a wide range of applications, including aerospace, automotive, medical devices, and more. The ability to produce components with tight tolerances and smooth surface finishes is a hallmark of professional turning services, enabling manufacturers to meet the stringent requirements of modern industries.

Enhancing Efficiency through Advanced Turning Technologies

Advancements in turning technologies have revolutionized the way components are manufactured. From computer numerical control (CNC) turning to multi-axis machining, modern turning services offer a diverse array of capabilities that empower manufacturers to streamline their production processes. By harnessing the power of automation, real-time monitoring, and precision tooling, turning services can significantly reduce lead times, minimize material waste, and enhance overall operational efficiency.

Quality Assurance and Inspection in Turning Services

Ensuring the quality of machined components is paramount in manufacturing. Professional turning services incorporate rigorous quality assurance and inspection processes to maintain the highest standards of precision and accuracy. Through the utilization of advanced metrology equipment and meticulous inspection protocols, manufacturers can have full confidence in the quality of the components produced through turning services. This commitment to quality is essential in meeting the demands of industries where precision is non-negotiable.

Streamlining Production Processes with Professional Turning Services

Streamlining production processes with professional turning services involves a holistic approach to manufacturing optimization. By integrating turning services into the production workflow, manufacturers can achieve seamless coordination between design, machining, and quality control. This integrated approach not only accelerates the production cycle but also enables continuous improvement through data-driven insights and feedback loops. The result is a lean and agile manufacturing operation that is capable of meeting the dynamic demands of the market.

In conclusion, the role of turning services in streamlining production processes cannot be overstated. From enhancing efficiency through advanced technologies to upholding the highest standards of quality, professional turning services are indispensable in modern manufacturing. By embracing the capabilities of turning services, manufacturers can position themselves for success in an increasingly competitive global landscape.